Xtrakt™ Standard Transforms Tyre Building Machine Operations with Real-Time Monitoring and Control

Industry: Manufacturing – TBM (Tyre Building Machine)

Download pdf

Challenges:

- The customer had difficulty in managing real-time visibility status of their tyre building machines.

- This made it difficult to monitor production progress and respond swiftly to concerns.

- Crucial analog parameters like pressure and temperature for the tyre building machines were not being tracked.

- The lack of this data obstructed their ability to maintain quality and consistency in their products.

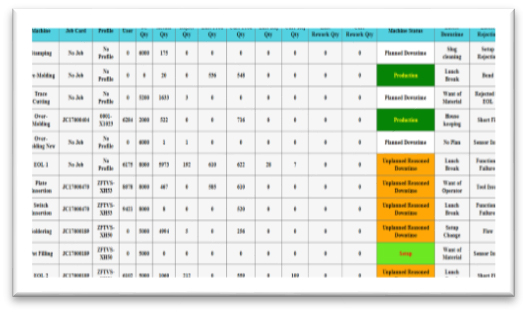

- Critical data related to operators, specific tyres, machines, timestamps, and downtime was not available.

- The lack of data made it difficult to identify bottlenecks and maximize their manufacturing processes effectively.

Our Solutions:

- Xtrakt™ Standard reduces unexplained stoppages and supports a more transparent production process by interlocking the machine and compelling the operator to offer reasons for downtime from a specified list.

- With Xtrakt™ Standard, safety checks are built into the workflow, ensuring that all required precautions are done before production begins.

- This tool compares planned and real production counts, allowing for fast modifications when variances occur and assisting the customer in meeting the production objectives.

- Ensuring operator adherence to standard operating procedures improves product quality and consistency while reducing mistakes and inconsistencies in production.

- Comprehensive downtime records are kept, assisting the customer in identifying recurring issues and offering insights for process development. This historical data is priceless for ongoing optimization.

- With Xtrakt™ Standard, obtain full insights into OEE at the plant, operator, and machine levels. This provides precise key performance indicators (KPIs) like utilization and efficiency, allowing the customer to make data-driven decisions for improvement.

- The Login Logout Time feature of Xtrakt™ Standard is an essential component for maintaining transparency and supporting data-driven decision-making by enhancing workforce management.

Benefits:

- Real-time data and insights enable planning and allocating resources more efficiently, streamlining manufacturing operations.

- Using scanning technology removes mistakes and improves data accuracy, enhancing the overall quality of operations.

- Machine interlock capabilities reduce downtime and promote transparency, allowing processes to function smoothly.

- A simple operator interface streamlines processes, making it easier for operators to handle and report data precisely.