Xtrakt™ PDA Revolutionizes Pyrolysis Process in Manufacturing

Industry: Manufacturing

Download pdf

Challenges:

- In Pyrolysis, any rapid or uncontrolled increase in temperature & pressure can cause accidents and endanger persons and equipment.

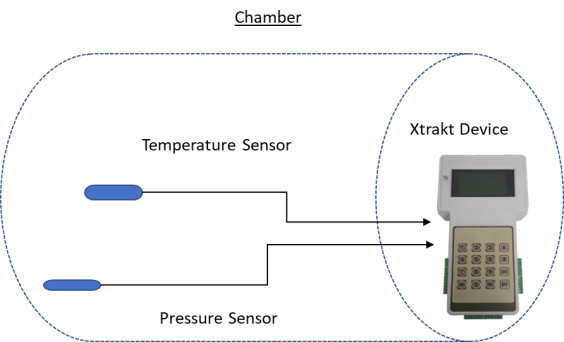

- It was difficult for the customer to retain real-time knowledge of the pressure within the chamber while heating. Accurate pressure monitoring is critical for process control and safety.

- To minimize accidents and assure product quality, early identification and action in cases of deviations from the standard were critical.

Our Solutions:

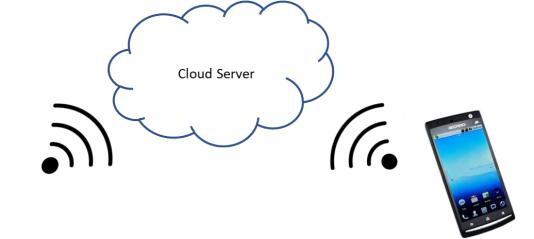

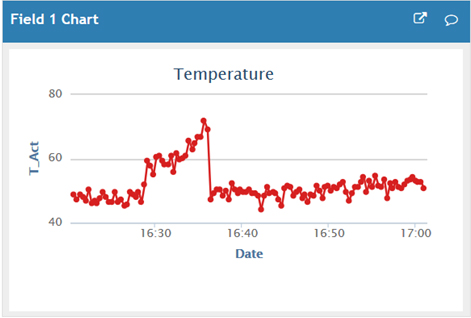

- The Xtrakt™ PDA uses a cloud server to log temperature and pressure data at 20-second intervals.

- This data is available for real-time analytics, allowing operators to closely monitor the process.

- The system integrates temperature and pressure sensor feedback, providing critical insights to operators and allowing them to respond quickly to any irregularities.

- Precise process control in pyrolysis is performed by opening and shutting a solenoid valve, which is handled by Xtrakt™ PDA. This automation guarantees that the progression is safe and regulated.

Benefits:

- Pyrolysis process improved significantly after using Xtrakt™ PDA.

- Real-time data access and monitoring enabled for more efficient planning and resource allocation.

- The use of scanning technologies reduced mistakes and increased data accuracy.

- The ability to interlock machines ensured that the pyrolysis process ran smoothly, lowering the chance of accidents.

- A user-friendly interface streamlined operations, making it easier for operators to precisely manage the pyrolysis process